RSI Equipment

Home » Environmental Remediation Equipment

With our patented S.A.V.E.™ Remediation Equipment

With RSI's PROGREEN® Technology

Produce electricity & sell it back to the grid with our generator units

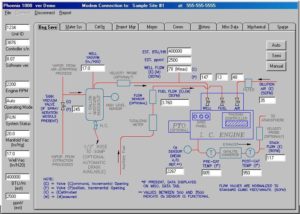

With Our Phoenix Remote Monitoring Telemetry System

Our Engine Units Run on Dilution Air - Save Time, Fuel, & Money

Non-entry technologies during industrial operations reduce hazards and improve safety. Our turnkey systems are easy to operate!

Base Unit w/ Optional S.A.V.E.™ & Bio SLurper Module

Base Unit - Trailer Mounted

Remote Monitoring Control System

PHOENIX HOST CONTROL SOFTWARE

DUAL & Multi PHASE EXTRACTION MODULES

Spray Aeration Module (Liquid/Liquid Heat Exchanger)

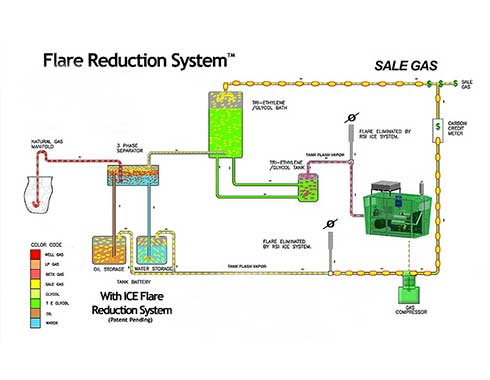

Flare Reduction System

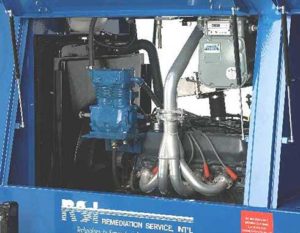

Module for HC Destruction & Cogeneration

High Flow Catalytic-Oxidation Module

Engine-driven Positive Displacement Blower for Air Injection

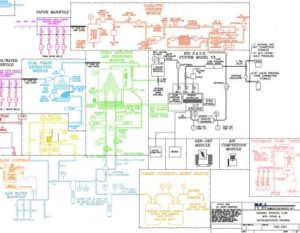

RSI Equipment Drawings, Schematics, & Manuals

Project Manager, Systems Engineering